Introduction to quartz crucible

Production materials - high purity quartz sand: SiO2 purity greater than 99.998%

Process technology - Arc melting:In fact, it is a kind of container, which is made of high purity quartz sand through mold setting and high temperature production by arc method. It has the characteristics of high temperature resistance, long service time and high purity, etc. It is mainly used as auxiliary consumables for semiconductor and solar drawn monocrystalline silicon rods.

World:In 1920s, TSL began to produce industrial quartz crucible by arc method

China:In September 1980, the Ministry of Building Materials organized a technical investigation team to Britain, Germany, Japan and the United States. In 1985, we introduced quartz crucible manufacturing technology and equipment for semiconductor from Japan's original Toshiba. Production began in early 1987.

At present, the domestic crucible can produce up to 46 inches.

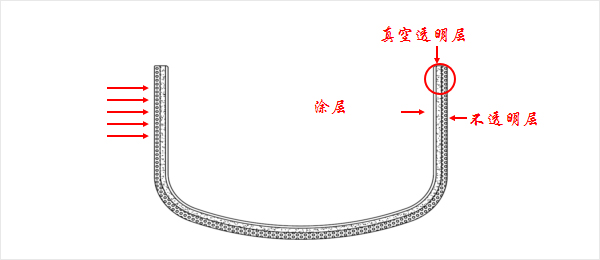

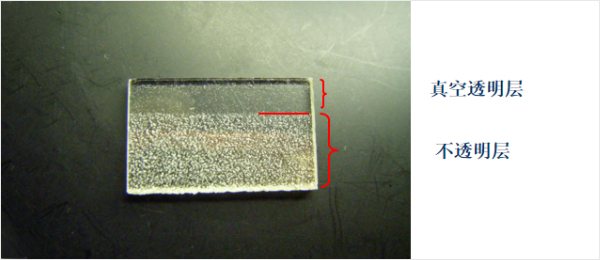

The crucible structure is divided into two layers:

The outer layer is an opaque layer (bubble layer) : the interior contains a large number of bubbles;

The inner layer is a transparent layer (vacuum layer) :uniform and dense, smooth surface, very few bubbles;

Thermal properties are mainly reflected in the following aspects:

① Deformation point 1075℃

② Softening point 1730℃

③ The maximum continuous use temperature is 1100℃, and the short time is 1450℃

The company is committed to the production and development of solar and semiconductor grade quartz crucible

Quartz crucible product sizes from 28 "to 42"

Why choose Jingshengwang quartz crucible

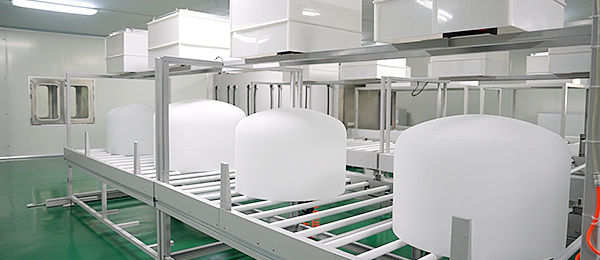

Adhering to the "quality first, customer first" quality policy, we introduce the domestic advanced crucible automation production equipment, equipped with millions of cost level clean workshop, intelligent control, rigorous processing, high speed operation in one, to help production efficiency and product consistency continue to increase. We select high purity quartz sand raw materials with a purity of more than 5N, and use steel molds with strict dimensions to melt quartz crucible into shape by arc method. At the same time, the sintering process is constantly improved to avoid any deviation of the finished product. All products are strictly carried out preliminary appearance size inspection and secondary depth inspection to accurately test product purity and temperature resistance, and through multiple ultra-clean cleaning, to ensure that the quality of the crucible meets the stringent requirements of the semiconductor industry and the energy industry, with 100% qualified rate of finished products, casting Jingsheng Wang's advanced products and well-known brands.